- info@zandsys.com

- Irvine, California, 92602 USA

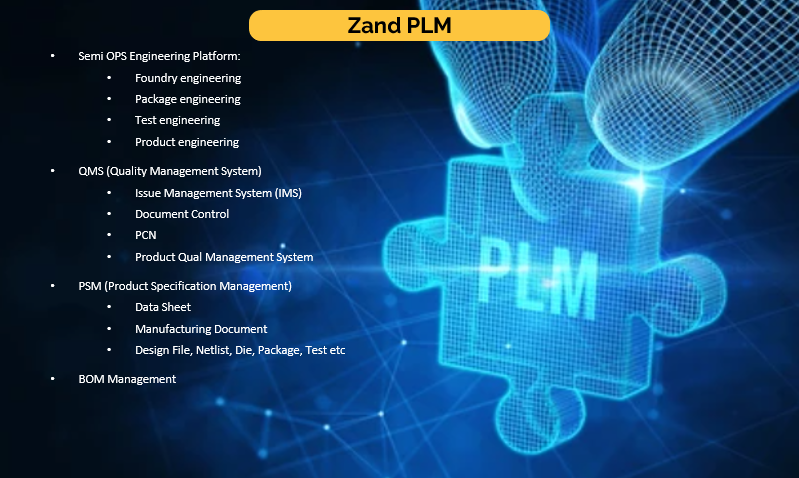

Semiconductor OPS PLM

About:

Title:

Maximizing Efficiency and Innovation: A Comprehensive PLM Approach for Semiconductor Operations

Abstract:

In the fast-paced and dynamic landscape of semiconductor operations, companies face a multitude of challenges ranging from coordinating with foundries to ensuring stringent quality control measures. This white paper delves into the intricate ecosystem of semiconductor manufacturing and presents a tailored Product Lifecycle Management (PLM) solution designed to streamline processes, enhance collaboration, and drive innovation.

By exploring the nuances of semiconductor operations and dissecting the capabilities of our comprehensive PLM application, this paper aims to provide insights into how companies can overcome obstacles and achieve sustainable growth in the industry.

Introduction:

Semiconductor operations operate at the cutting edge of technology, constantly pushing boundaries to meet the demands of an ever-evolving market. However, this pursuit of innovation comes with its own set of challenges, including complex supply chains, rigorous quality standards, and rapidly advancing technologies. In this context, effective management of the product lifecycle becomes crucial for success.

This white paper aims to explore the multifaceted challenges faced by semiconductor operations and present a holistic PLM solution tailored to address these challenges.

Challenges in Semiconductor Operations:

Semiconductor operations encounter a plethora of challenges across the product lifecycle, each requiring careful navigation and strategic management. These challenges include:

· Foundry Management: Coordinating with foundries for chip fabrication Ensuring adherence to design specifications and quality standards

· Product Development: Navigating through multiple iterations of chip design, prototyping, and validation Meeting performance, power, and cost targets

· Package Design and Integration: Developing suitable packaging solutions for optimal performance and reliability Ensuring manufacturability of semiconductor devices

· Test Strategy and Execution: Implementing robust testing methodologies for defect detection and functionality assurance Enhancing yield rates through efficient test execution

· Manufacturing Optimization: Streamlining manufacturing processes to optimize resource utilization Managing supply chain complexities for seamless production

· Quality Control, Compliance & Document Control: Enforcing stringent quality control measures to mitigate risks and uphold brand reputation Ensuring compliance with industry regulations and standards

ZandPLM Advantages:

Our Semiconductor Operations PLM application offers a comprehensive solution to address the diverse needs of semiconductor operations.

Key features of our PLM application include:

· Foundry Collaboration: Seamless communication and collaboration with foundries Integration with foundry-specific tools and platforms for alignment throughout the manufacturing process

· Product Lifecycle Management: Managing the entire lifecycle of semiconductor products Version control, revision management, and traceability of design changes for consistency and transparency

· Package Design and Simulation: Tools for package design, thermal analysis, and signal integrity simulation Integration with CAD tools for real-time design validation and optimization

· Test Planning and Execution: Comprehensive test planning and strategy definition Integration with automated test equipment for efficient test execution and data analysis

· Manufacturing Process Management: Workflow automation, resource scheduling, and production monitoring capabilities Integration with MES and ERP systems for seamless data flow and visibility

· Quality Control and Analytics: Advanced analytics and statistical process control techniques for real-time monitoring Integration with quality management systems for proactive quality management and continuous improvement Benefits of

· Enhanced Product Quality: Robust quality control measures and proactive defect detection mechanisms ensure high-quality semiconductor devices

· Cost Optimization: Optimization of manufacturing processes and resource utilization leads to reduced operational costs

· Regulatory Compliance: Built-in compliance features ensure adherence to industry regulations and standards

· Scalability and Flexibility: Scalable architecture and configurable modules accommodate evolving business needs Conclusion: In conclusion, a tailored Semiconductor Operations PLM solution is essential for semiconductor operations to thrive in today's competitive landscape. By seamlessly integrating various functionalities, our PLM application empowers companies to overcome challenges, drive innovation, and achieve sustainable growth. Experience the transformative power of our PLM solution and unlock new possibilities in semiconductor operations.